Capabilities

At Dyna-Graphics, our product capabilities include membrane switches, touch screens, graphic overlays and much more. For each of these things, we offer a wide range of options, ensuring that the finished product matches your designs and needs perfectly.

Membrane Switches

- Tactile/Non-Tactile

- Screen Printed Silver or Copper FPC Circuitry

- Imbedded LED Circuits

- Environmentally Sealed

Graphic Overlays

- Screen Printed Graphics

- Digital Printed Graphics

- Embossing

- Protective Hard Coating

PCB Assemblies

- Rigid FR4 Circuitry

- Value Added Components

Touch Screens

- 4-5-8 Wire Resistive

- Custom and Stock Sizes

- Capacitive

Membrane Switch, Resistive Touch Screen & Rubber Keypad Manufacturing Equipment

At Dyna-Graphics, a key strategy to enhance the overall capabilities of the organization is to consistently invest in state-of-the-art equipment to bring you the best membrane switch, keypad, and resistive touch screen products. This investment in production capabilities, combined with experience and ability to meet clients' specifications in terms of engineering, prototyping and production, allows Dyna-Graphics to remain the recognized leader in membrane switch technology. Among the systems that have been recently invested in include a FlexPacer pick and place machine and a FlexLaser II Carbon Dioxide (CO2) Laser Cutter.

FlexPacer – Membrane Switch Technology

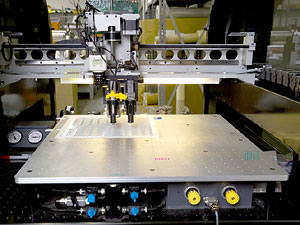

The FlexPacer pick and place machine gives Dyna-Graphics the capability to precisely place LEDs, as well as to repeat the LED placement process in an exact manner. Furthermore, the FlexPacer allows for the rapid and accurate placement of metal domes – also referred to as automatic doming – again, an important part of Dyna-Graphics' membrane switch technology. In addition, the FlexPacer includes an advanced software package allowing for straightforward importation of engineering files – resulting in minimal programming and component set-up time.

Dyna-Graphics uses The FlexLaser II to accurately and precisely cut materials. With a 36-inch by 48-inch table, the FlexLaser II can handle full size material sheets, which eliminates the need for an initial shearing operation step, thereby expediting the cutting process. Another benefit of the FlexLaser II is that it produces a small diameter laser beam – this allows hard-to-cut materials to be sliced with excellent edge quality and surface finish. Again, the purchase and use of both the FlexPacer and FlexLaser II systems is indicative of Dyna-Graphics' ongoing commitment to constantly meet the changing needs and requirements of our customers.

Digital Printing

Dyna-Graphics uses digital printing to customize our membrane switches and graphic overlays for our customers. Recently, we brought all of our digital printing in-house with the purchase of a Roland digital printing press, which was installed in a controlled environment room. Utilizing essentially the same technology as an office printer, our digital printing capabilities allow us to add graphics, logos, text, and more.

Advantages of Digital Printing

Unlike screen printing, our digital printing system can create numerous effects, including:

- Multiple-color designs

- Color cross-fading

- 3-D graphics

- Textures

- And more

The LED-cured UV ink holds up better than screen printing. By printing on the backside of membrane material, your graphics can be made scratchproof and impervious to environmental factors. Our own processes of encapsulating the digital ink systems with traditional screen printing systems ensure our customers receive the high quality products they have always expected from Dyna-Graphics. We produce prototypes quickly and economically with digital printing technology, but the process is useful for all our products. Dyna-Graphics' digital printing offers nearly unlimited graphic possibilities.

Membrane Switch Technology – Resistive Touch Screen, Membrane Keypad & High Level PCB Assembly

Other Dyna-Graphics' capabilities include membrane switch technology high-level assemblies, with practically box-build potential. With our Chinese manufacturing source, Dyna-Graphics can act as the client's co-op partner, building complete printed circuit board assemblies, gaskets and resistive touch screens (utilizing injection molded plastics), along with long ribbon cables (depending on the application). Basically, Dyna-Graphics is a true interface contract manufacturer, with over 35 years of extensive experience and knowledge in the design, development, prototyping, production, and testing custom membrane switch technology.

Engineering Capabilities

At Dyna-Graphics, we're committed to our customers' success. To that end, our engineers provide a wide range of additional services such as:

- Conceptual design services

- Circuit layout

- Production art services

- Proofing

- Prototyping

- CAD design

- Innovation based on customer needs

Contact Dyna-Graphics

Contact Dyna-Graphics with your custom membrane switch, rubber keypad, or touch screen project today.